Leading manufacturer of railing systems

Pespa Alumin is an established brand in designing, manufacturing, standard and customized railing systems.

Based on technical know-how and 30 years of experience, we provide a high-quality range of aluminium railing systems, all in one supplier with a closed cycle manufacturing process starting from customized design projection, aluminium extrusion, mechanical production, and anodizing up to assembly.

- Professional manufacturer within Europe

- CE Marking manufacturing process

- Rapid samples design and delivery

- Personalized assembly and packaging

- Architectural sales consultants

- Customized static calculations to meet the requirements of a specific project

- Guaranteed total quality

ALUMINIUM RAILINGS

DECORATIVE METAL SHEET BALUSTRADE

DECORATIVE WELDED RAILING

VERTICAL BALUSTRADES

Aluminium Deck Railing

GLASS RAILINGS

On side mounting glass railing S5285

Modern Glass Balcony Railing S5046

Glass Panel Railing

High Rise Glass Railing

FRAMELESS GLASS RAILINGS

Frameless glass railing with posts – A SERIE

Continuous profile frameless glass railing- B SERIE

High rise frameless glass railings- C-SERIE

Glass posts and clamps systems

COMMITTED TO TOTAL QUALITY

RAILINGS MANUFACTURING PROCESS AT PESPA ALUMIN

DESIGN AND ENGINEERING TECHNICAL SOLUTIONS

- Project analysis and evaluation, ensuring all technical requirements and building regulations are fully integrated into the product development process.

- Technical solutions to meet specific project requirements

- Fast prototype production

- Accredited European laboratory testing of the product’s function.

- Rapid preparation of samples for on-site testing and prototype approval.

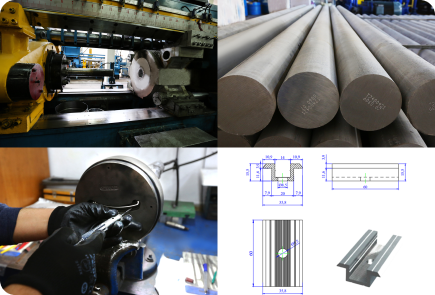

EXTRUSION OF CUSTOMIZED ALUMINIUM PROFILES

- Design and production of aluminium dies based on custom drawings

- Selection of aluminium billet alloy suited to the final product’s functionality for architectural or industrial use

- Extrusion process carried out in compliance with EN 15088:2005 standards

- Strict quality control of primary allow chemical composition and minimal/ maximal tolerances based on aproved samples and technical drawing

- Rigorous quality control in accordance with EN 573-3 for aluminium profiles

ALUMINIUM RAILING ACCESSORIES PRODUCTION

- Manufacturing of aluminium railing accessories using advanced automatic and CNC machines, in compliance with EN-10204 and EN-1090 standards.

- Processes include milling, drilling, turning, and threading, offering various shapes such as square, rectangular, circular, conical, and elliptical.

- Internal testing for coupling and dimensional accuracy.

- Strict quality control throughout production, ensuring compatibility with profiles and accessories for assembly or welding.

ANODISATION AND POWDER COATING OF ALUMINIUM PROFILES, ACCESSORIES AND SEMI-PRODUCTS

- Anodizing aluminum accessories and aluminium assembled products in small, medium and large dimensions.

- Powder coating of aluminium railings components and semi-finished products.

- Total Quality guarantee.

- Quality control based on design and project specifications.

ASSEMBLY OF RAILING POSTS AND SEMI-FINISHED OR FINISHED PRODUCTS

- Assembling of railing kits and both semi-finished and finished products.

- Coupling customized products with their relevant elements and screws and bolts to be installed as per customized design.

- Ce marking in compliance with and EN-1090 standards with EN-10204. compliance for welding and assembly.

- Strict quality control of primary allow chemical composition and minimal/ maximal tolerances based on aproved samples and technical drawing

PACKAGING SOLUTION AND LOGISTICS

- Packaging and labeling based on best practices and specific customer requests.

- All necessary permissions and licenses provided, ensuring compliance with free trade agreements for shipments under EXW terms via land, sea, and air.

- Conveniently located near the Port of Durres, one of the Adriatic Sea's major ports.